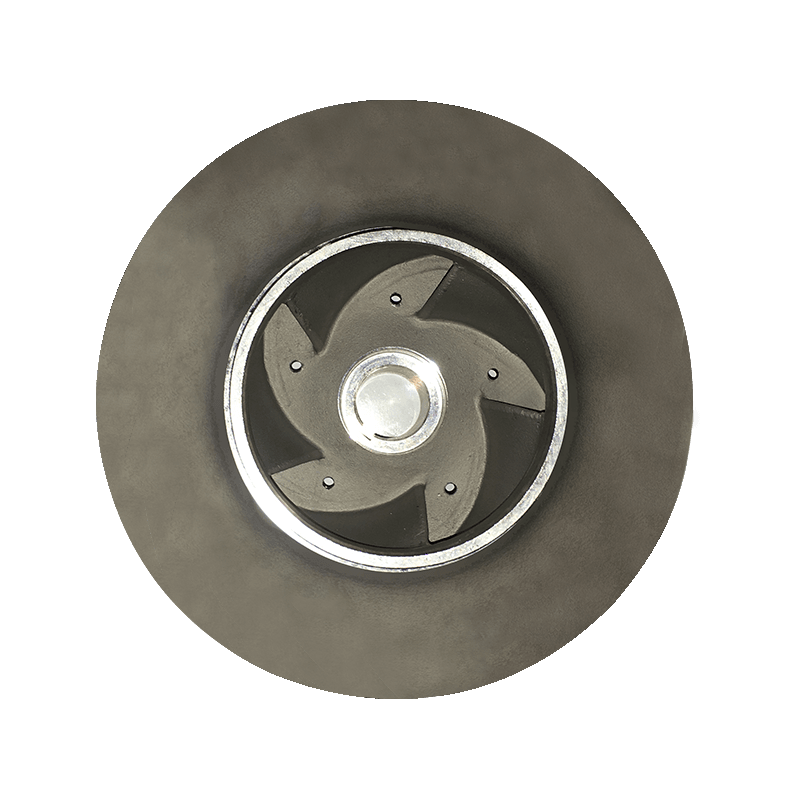

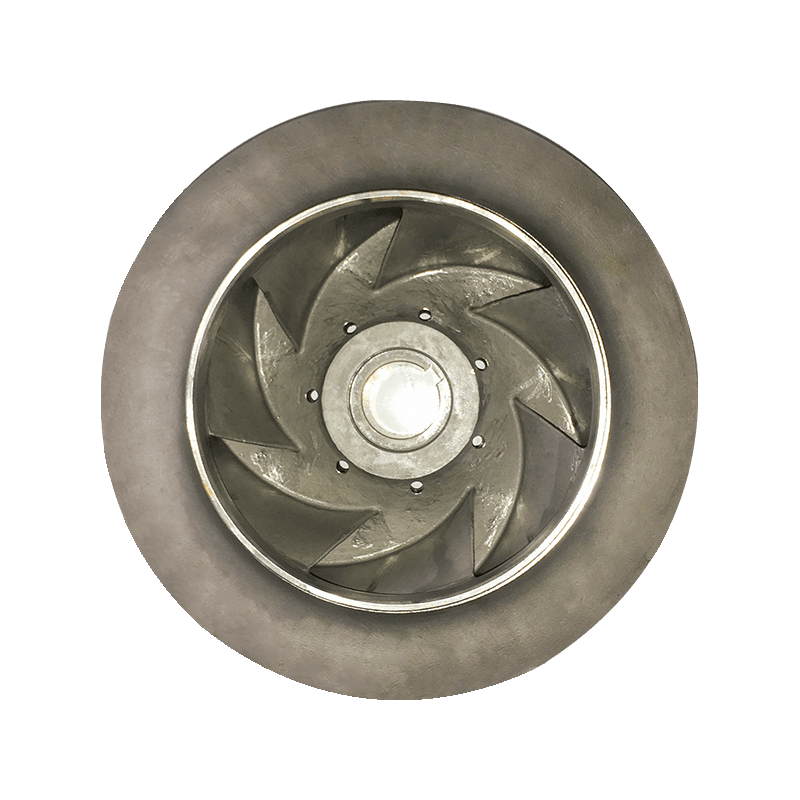

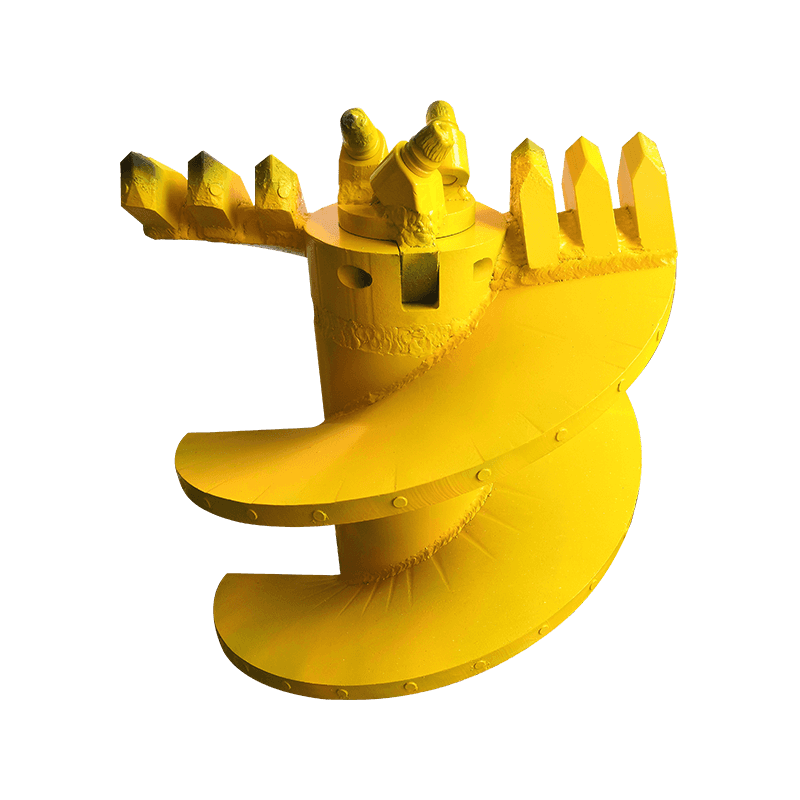

ROSIO est unus ex maxime pertinax provocationes in sentinam systems, praecipue in industries quasi eget processus, marine ipsum et wastewater curatio. Cum sentinam components degrade propter chemical reactiones aut environmental nuditate ducit ad pretiosi downtime reducitur efficientiam et salute metus. Inter critica pump partes: impellers -Responsible translationem industria a motricium ad fluidi, sunt maxime vulnerable. Hoc ubi immaculatam ferro mittentes technology lucet. Per leveraging provectus metallurgical proprietatibus et praecisione ipsum, immaculatam ferro impellers offer otiosum corrosio resistentia.

I. De Scientia in immaculatam ferro scriptor corrosio resistentia

Stainless ferro est ferrum, secundum Alloy quibus minimum 10.5% Chromium. Hoc chromium Reacts cum oxygeni in environment ad formare passiva, auto-sanando cadmiae layer (crito₃) in superficiem. Hoc invisibilia film agit in obice, prohibendo mordax agentia sicut chlorides, acida, aut alkalis ab penetrating metallum subiecta. Nam impellers operating in infestantibus media, ut searchater, acidic chemicals, aut summus salinitatis fluidorum-hoc proprietas est discrimine.

Maximum-perficientur grades sicut 316L immaculatam ferro (quibus 2-3% Molybdenum) porro augendae resistentia ad pitting et Creprocus corrosio chloride-dives ambitus. Similiter Duplex Stainlless Steels (E.G., MMCCV) miscere Austenititic et Ferrans Structuris superioris viribus et corrosio resistentia in extrema conditiones.

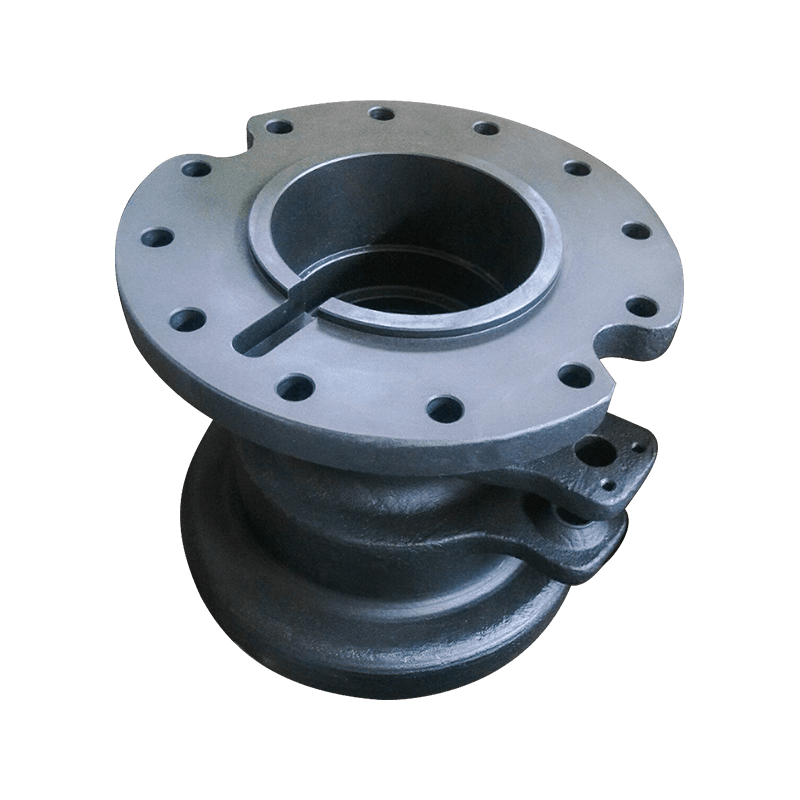

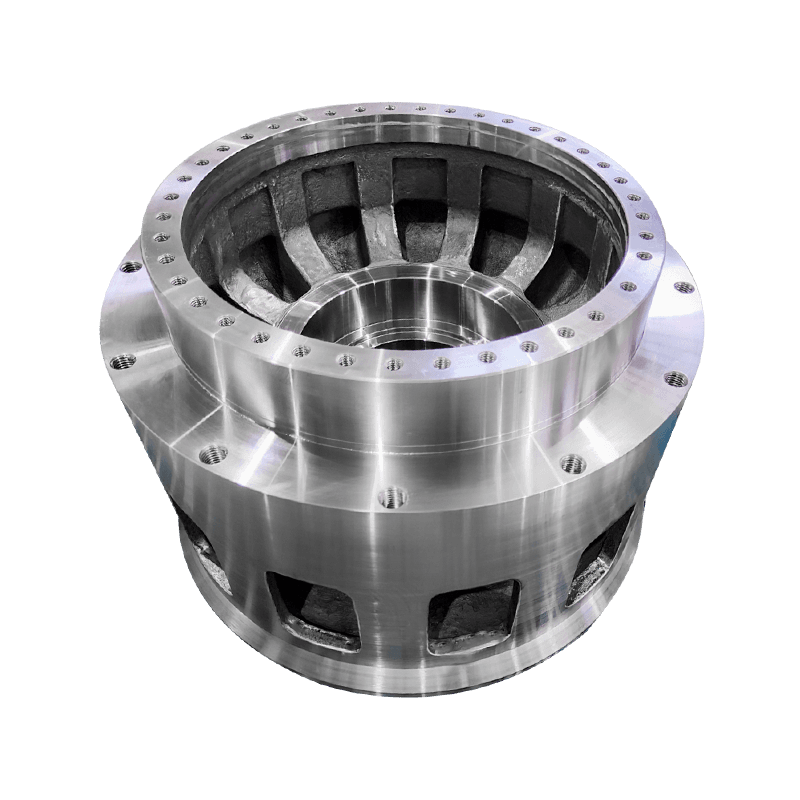

II. Precision mittitus infirma punctorum

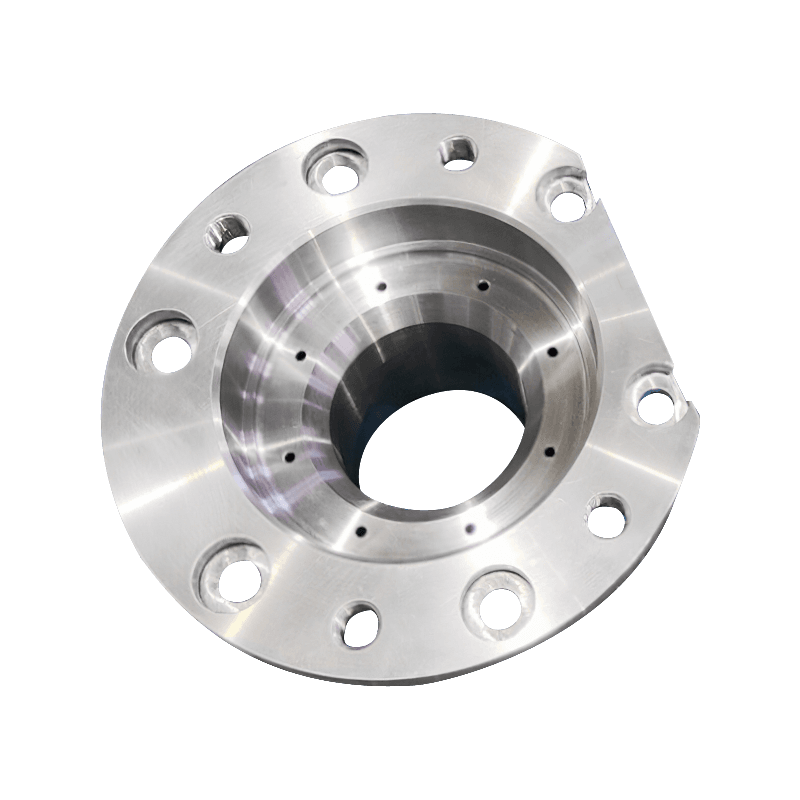

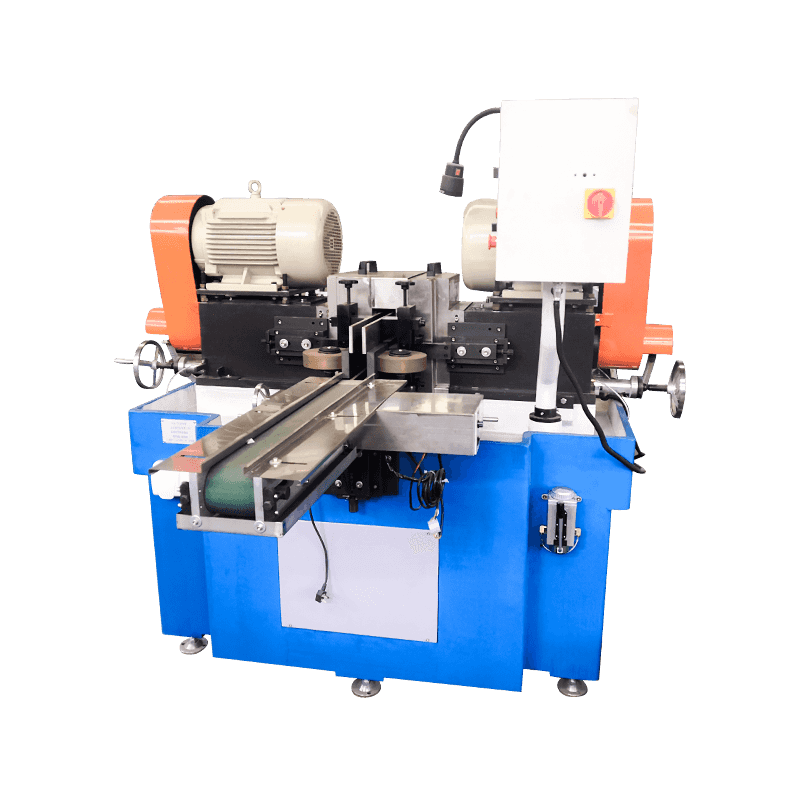

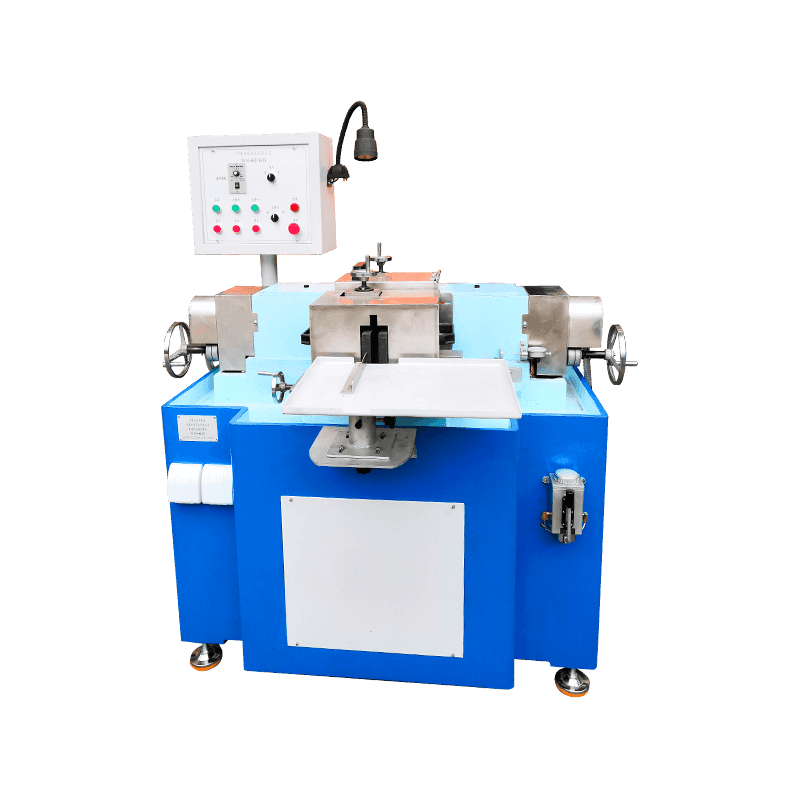

Et corrosio resistentia immaculatam ferro impellers non solum de materia choice-suus 'etiam de vestibulum praecisione. Mittentes processibus quasi obsideri casting aut harenae casting curare:

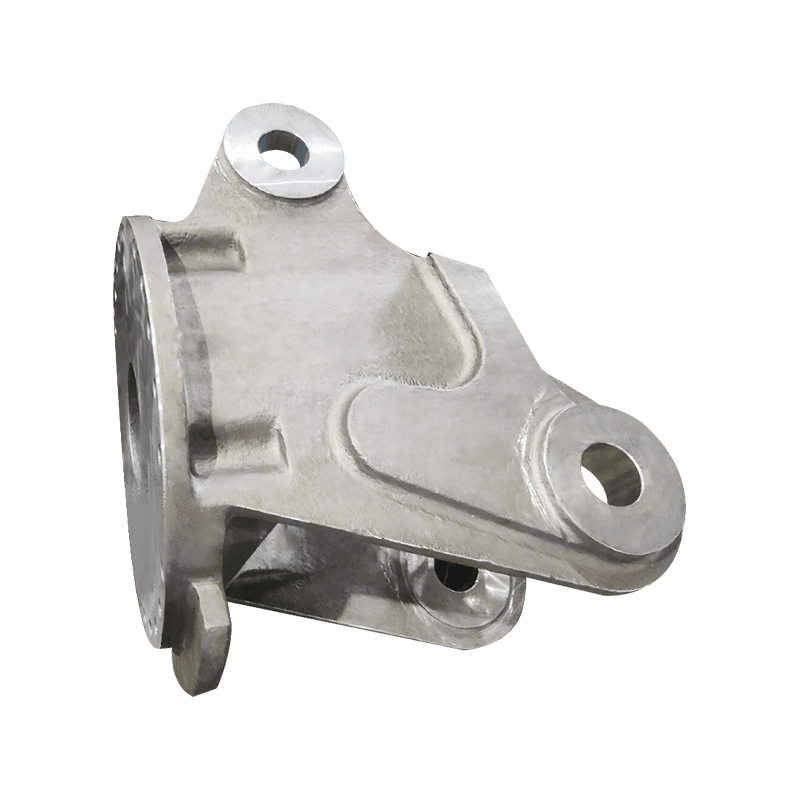

Uniform Microstucture: Minimizes evacuat, inclusions, aut inaequaliter frumenti terminos, quae posset initium corrosio.

Geometriam complexu integritate: seamless shapes reducere crevices ubi stagnarum fluidorum ut cumulare et corrode superficiei.

Superficies metam imperium: levior superficiebus, in reipubilem per post-casting treatments sicut electrolytic politicibus, reducere adhaesionem mordax deposits.

Contra, male solidum aut machined partibus saepe develop microstructural defectibus, accelerating localized corrosio.

III. Tailored Alloys ad propria environments

Steel stainless scriptor versatility concedit engineers eligere meliorem grades secundum sentinam in operating conditionibus:

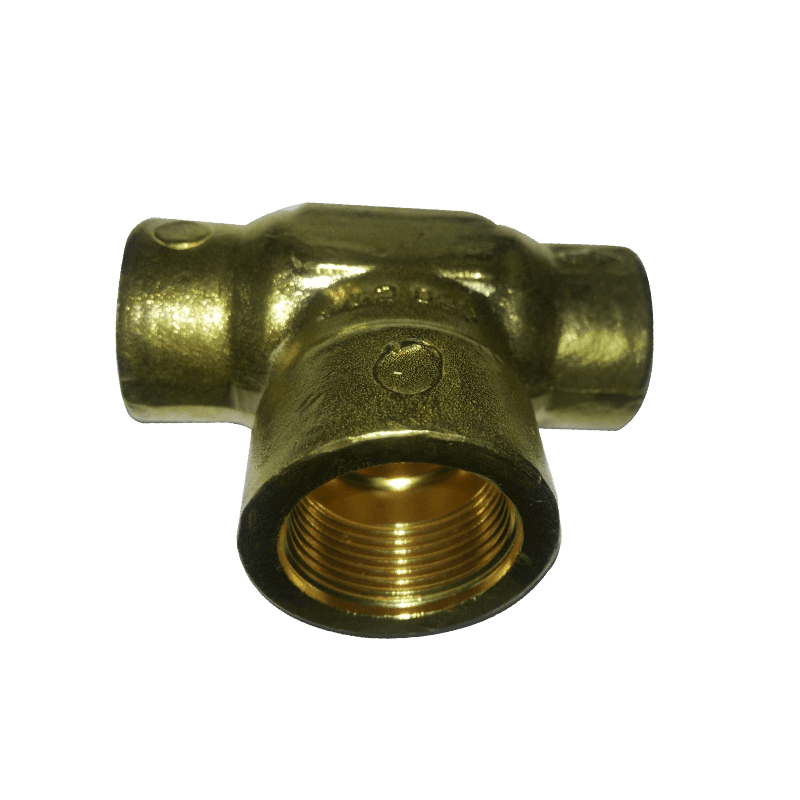

Marine Applications: Super Duplex Stainless Steels (E.G .: S32750) sustinere saltwater scriptor chloride ions.

Donec Processing: High-Alloy grades sicut 904L resistere sulfurica et phosphoric acida.

High-temperatus fluids: Austenititititititititen Steels (E.G., CCCX) ponere stabilitatem in scelerisque cycling ambitus.

Exempli gratia, in in a desalination plant, 316L impeller scriptor Molybdenum contentus impedit chloride-adductus pitting, extendens Service Vita per 40-60% comparari carbonis ferro Alternatives.

IV. Galvanic et erosion corrosio

Aliud immaculatam ferro impellers et mitigare duo minus obvious corrosio machinationes:

Galvanici corrosio: cum Dissimiles Metals Contact in PROLIXUS fluidorum, galvanica cellulis forma. Stainless ferro nobilis electrochemical potentiale reduces hoc periculo cum paribus compatible materiae.

Exesa, corrosio, summus velocitate fluidorum potest induendum defensiva cadmiae layers. Inherent duritia et lenta dejecta immaculatam ferro (E.G., brinell duritia 150-200 PB) resistere abrasione, conservando passivum film.